When it comes to chemical equipment, safety is the top priority – closely followed by efficiency. With this in mind, we manufactured five acid-proof tanks for a battery factory in Debrecen. The chemical storage tanks were made from stainless steel provided by the client, along with the designs. However, the quality of the finished product was relied heavily on the precision and technology of our manufacturing process.

Manufacturing chemical storage tanks needs to comply with exceptionally high-quality standards, which is why an external third party was involved in the verification process. In our article, we’ll walk you through the steps of manufacturing the tanks for the Debrecen battery factory and the independent inspection process that confirmed their quality.

Manufacturing chemical storage tanks from stainless steel

Manufacturing process of the chemical storage tanks

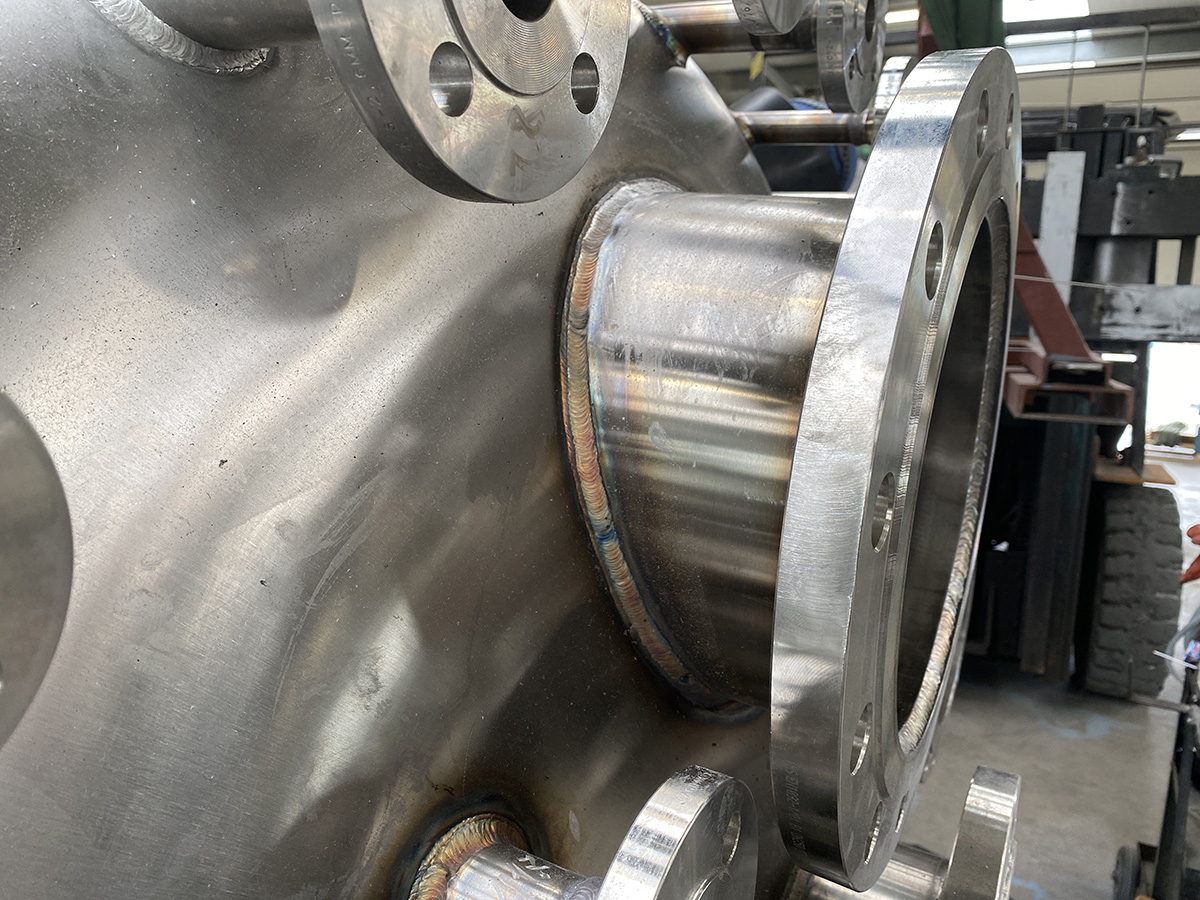

The tanks were made from 1.4301 stainless steel. The supplied materials included sheets, flanges, and pipe sections. Production involved rolling, assembly, welding, and surface finishing.

Special surface roughness standards applied to these tanks to prevent material buildup during use.

Achieving the required finish took significant time and attention, using a combination of specialized tools and abrasives. To ensure compliance, we measured surface roughness with precision instruments throughout the process.

Chemical storage tank under production

As pressure vessels operating at 4 bar, these tanks required particular focus on structural strength and reliability.

As you can see, producing these chemical tanks was a complex task that demanded expertise, precision, and efficient workflow management—especially under tight deadlines where speed could not come at the expense of quality.

Third party verified quality

To ensure the quality of the manufactured chemical storage tanks, strict acceptance criteria included a special charge. Before the tanks were shipped, these charges were hold at our workshop in Kisapostag.

Weld seam of the chemical storage tank

During acceptance, an third-party certification company was responsible for inspecting the surface

- surface finishing,

- welding quality, and

- pressure resistance.

During pressure testing, the tanks were subjected to 6 bar to verify their structural integrity.

Additionally, a second independent agency conducted X-ray inspections of the welds to ensure flawless quality and long-term pressure resistance and corrosion protection.

High added value in tank manufacturing

We prioritize quality in every project. Our tanks meet strict industry standards, guaranteeing optimal performance and long service life, even in extreme environments.

Our references include companies from the wine, chemical, and rubber industries. If you need a highly durable, custom-designed tank that meets special technical and environmental requirements, you can rely on us. Thanks to our experienced team and advanced manufacturing processes, we deliver stainless steel tanks tailored to your exact needs.